Modification solutions

Maintain safe, reliable operation before and after modifications

Whether it’s for safety or economic reasons—or to correct existing design deficiencies or aging issues—permanent and temporary modifications to existing power plants are expected to increase in the years ahead.

Working with GEH can help ensure that your plant continues to meet its expected design specifications and safety standards in the face of sometimes-essential changes.

Jet pump anti-vibration system (AVS)

This solution helps mitigate damage due to coolant flow-induced vibration (FIV) caused by slip joint leakage FIV, turbulence, and crossflow.

The jet pump anti-vibration system was created to replace the set screws and main wedge at the jet pump restrainer bracket location. It maintains positive 3-point contact between the restrainer bracket and inlet mixer. Jet pumps with the AVS installed have significantly less inspection findings and improve outage efficiency.

- Addresses main wedge and rod wear, restrainer bracket wear, setscrew gaps, and slip joint FIV

- Addresses root causal factors at restrainer bracket location

- Extensively tested by EPRI (full-flow test) and GEH’s expert team (shaker table)

- Includes installation of slip joint clamps, hard and compliant stops

In-line feedwater debris strainer (FWDS)

Built to capture and retain debris in feedwater, thus preventing costly debris-related fuel failures.

Constructed to be installed in-line with existing feedwater flow lines on either the suction or discharge side of the reactor feedwater pumps, the FWDS can capture 100% of wires and particles above 0.016" diameter (including brush bristles) while maintaining flow performance with minimal pressure drop.

Steam separation

Steam dryer fatigue failures prompted the USNRC to implement a protocol requiring licensees to perform plant-specific steam dryer fatigue analyses to replace original equipment.

GEH’s current replacement steam dryer (RSD) design was subjected to extensive fatigue analyses performed at both current licensed thermal power (CLTP) and extended power uprate (EPU) conditions. It is the only “Non-prototype category I” RSD design that the NRC accepts and can be adapted to your specific plant configuration.

Tools

Specialty tools for nuclear modifications

Cattle chutes

A cattle chute is radiation shield used while transferring fuel rods from the reactor core to where the fuel is stored. They also protect workers in the case of a dropped fuel assembly.

Currently manufactured cattle chutes are much wider than their predecessors, which allows fuel to be transferred even quicker. Employing one of these new chutes is also useful when older chutes have become contaminated, or if plants don’t have the ability to remotely install or remove fuel.

Strongbacks

Strongbacks make lifting heavy loads safer because they can replace fragile slings. They reduce waste and contamination when working in water and eliminate the need to put people at heights to set rigging up. They can also be remotely operated by air panels.

Some large items strongbacks help to lift:

- Reactor pressure vessel (RPV) head

- Dryers

- Separators

- Shield blocks

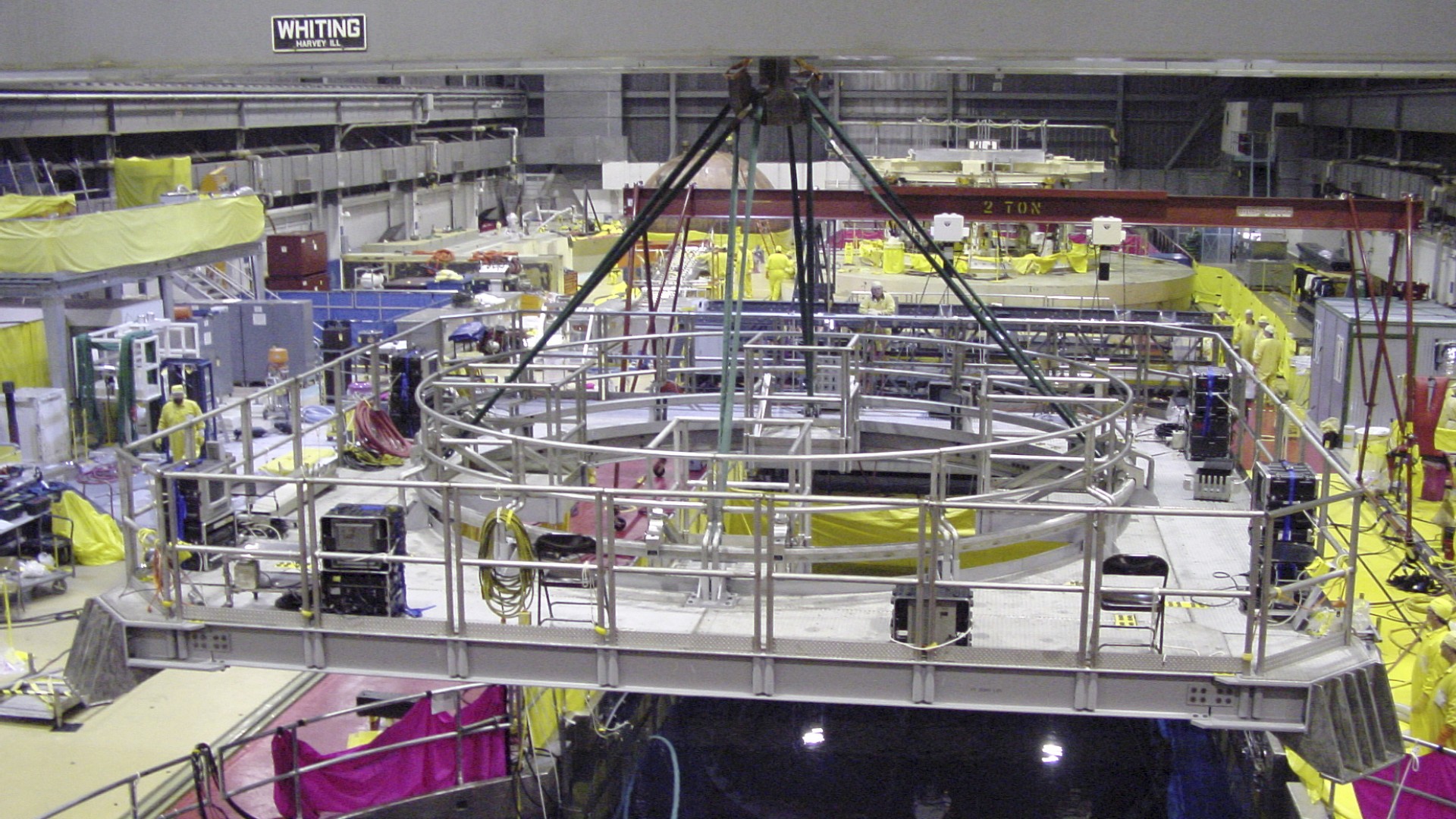

360-degree work platforms

Platforms allow workers to perform work while moving fuel into and out of the reactor core. With this tool, the Refuel Bridge (RFB) can easily travel over individuals working on the platform. It allows work to be performed in parallel and can also be an important component for supporting in-vessel maintenance.